Natural gas storage facilities - clever technology for security of supply in Germany

It is just around the corner - the winter that many are trembling about. As the warm summer months slowly fade, concerns about security of supply are growing - especially for natural gas. The long-criticized dependence on Russian imports is now taking its toll, and politicians are desperately trying to fill Germany's gas storage facilities until winter. At least the infrastructure is in place: Our gas storage facilities offer ample capacity by European standards, and we have an excellently developed gas network. But how do gas storage facilities actually work and why is stockpiling so important? In this article, we provide an overview with exciting facts about gas storage facilities and supply security in Germany.

Natural Gas Facts: Demand and consumption in Germany

Germany is one of the countries with the highest natural gas consumption in the world. Every year, we consume around 80 to close to 100 billion cubic meters in the Federal Republic. The gas comes almost exclusively from abroad - and until a few months ago, around half of it came from the Russian Federation. Natural gas is not only important for private households and public institutions. With a share of more than 36 percent of total German consumption, industry is the largest consumer. Natural gas is (still) the most important energy source for industrial manufacturing processes - for example, in aluminum production.

Good to know: Natural gas is in itself a transparent and odorless gas. The fact that it emits an unpleasant odor is actually a safety measure. Gas network operators usually mix in sulfur-containing odorants. This makes leaks in gas lines, for example, more noticeable. This admixture is known as odorization.

Courage to the gap or full storage? This is the state of gas stocks in Germany

After the historically low levels until spring 2022, the topic of gas storage really heated up politics and the energy industry. As an importing country with a high demand for gas, ample gas stocks are essential for Germany so that neither households sit in the cold nor economic performance is jeopardized. In fact, things are looking good at the moment. Savings measures and new sources of supply are enabling successful stockpiling. According to the German Federal Ministry of Economics and Climate Protection, the statutory interim targets for October 2022 can probably be achieved as early as September 2022.

Good to know: The new Gas Storage Act, which came into force in April 2022, regulates how many gas stocks Germany must build. Under the amendment, gas suppliers are required to gradually fill storage facilities by winter.

These are the legal fill level requirements until the cold season:

- 85 percent by Oct. 1, 2022

- 90 percent by Nov. 1, 2022

Beyond that, gas storage levels are to be at least 40 percent by Feb. 1, 2023.

Gas storage facilities in Germany

Why do we need to store natural gas in Germany? After all, can't new gas flow via pipelines or be brought here by liquefied natural gas tankers at any time? Unfortunately, it's not that simple in practice. In fact, gas storage facilities make an important contribution to the stability and flexibility of the gas network and to security of supply in Germany:

- Natural gas consumption is not constant and varies greatly by season - even significantly over the course of the day. Gas storage facilities ensure a reliable and continuous supply throughout the year, even during consumption peaks in the network.

- Gas storage facilities are often located close to consumption sites or at the interconnection points of the gas pipeline network. The energy carrier is thus physically available at short notice and immediately. This eliminates possible waiting times due to subsequent deliveries.

- Gas volumes that have already been purchased and stored are not subject to the sometimes drastic price fluctuations and the increasing demand on the market in winter. In this respect, stockpiling offers price security.

- Last but not least, security of supply can be maintained via gas storage facilities even if foreign suppliers fail to deliver due to technical, economic or political reasons.

Good to know: With a volume of around 24 billion cubic meters, Germany has the largest storage capacities for natural gas in Central and Western Europe. This would enable us to supply the entire country independently for two to three cold winter months without imports. In this way, natural gas storage facilities make a very important contribution to security of supply.

How do natural gas storage facilities work?

In fact, there is not one large gas storage facility in this country that supplies the entire country. Germany has many different storage facilities. In principle, the gas storage facilities function like huge tanks in which the injected natural gas is temporarily stored - underground. There are gas storage facilities such as steel spherical gas tanks that are above ground. However, these have a very small capacity and would not be technically or economically feasible on a larger scale.

The situation is quite different for underground gas storage facilities in Germany. In the case of so-called underground storage facilities, clever engineers are making use of storage sites that have already existed for a long time - in our natural environment. Germany has numerous geological structures that are ideal for use as gas storage facilities:

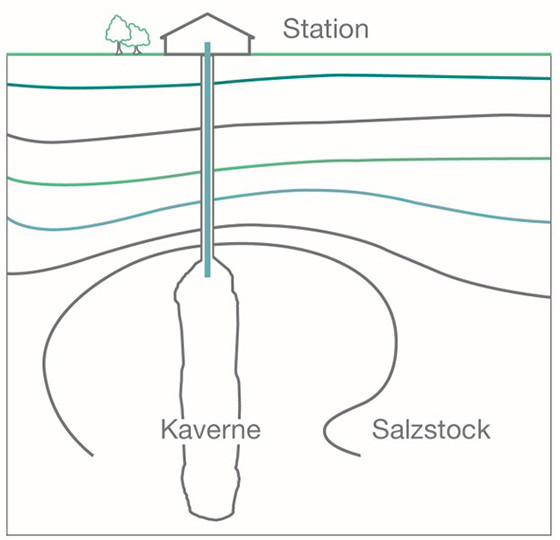

Salt caverns

Underground salt domes exist primarily in northern Germany. Some of them are huge structures that are being converted into gas storage facilities. This has been happening in this country since the 1960s. To do this, a cylindrical cavity in the salt dome is flushed out. The resulting cavern makes a great gas storage facility due to the sealing properties of the surrounding salt rock. The natural gas to be stored is then injected at very high pressure from the surface into the cavern through bore tunnels about the thickness of an arm, and then withdrawn as needed.

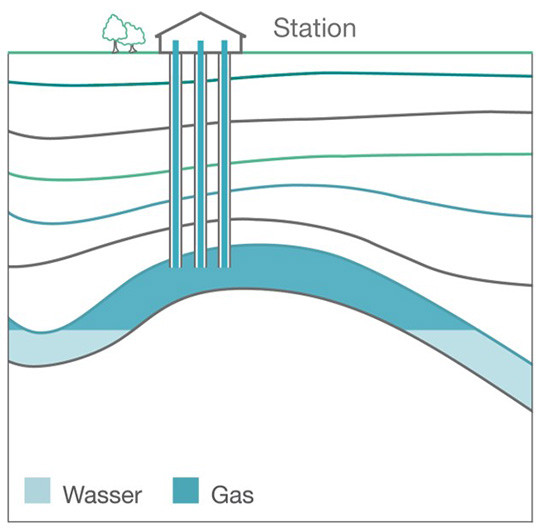

Pore storage

Certain types of rock can absorb gases or liquids like a sponge. These typically include sandstone, which has many small cavities and thus a lot of storage space due to its porous structure. If corresponding rock formations then lie beneath a sealing layer such as clay, they are ideal gas reservoirs. The gas cannot escape underground. Exploited, i.e. former natural gas or crude oil reservoirs are also used as pore storage facilities.

Good to know: Even if a lot of natural gas is needed in the network, the operators of gas storage facilities never withdraw the entire storage volume. A residual quantity of gas always remains underground. This so-called cushion gas maintains a minimum pressure so that the geological structure of the storage facility remains stable and does not collapse. Engineers call the portion of the storage volume that can actually be used working gas.

More than a depot: gas storage facilities are marvels of engineering

Sprawling plant complexes are located above the huge underground structures of natural gas storage facilities. They consist of numerous machine buildings and piping systems, in front of which laymen usually stand with a perplexed look. In fact, there is a lot going on here. Natural gas storage facilities do much more than just store and retrieve gas at depth:

- The natural gas delivered from long-distance pipelines is usually not yet suitable for storage. A filter system therefore first cleans it of dust and other small particles.

- In the next step, the quality of the gas is tested using complex measuring methods.

- The gas is recompressed in compressor stations. This increases the pressure enormously, which has a major advantage: Highly compressed gas takes up less space underground and the excess pressure makes it easier to withdraw.

- During withdrawal, the gas has to be dried and heated because it usually absorbs moisture at depth. This is done in special gas drying plants.

- Finally, the pressure is adjusted to the level of the gas network for an outfeed and heated.

Basics of the energy market: gas storage in Germany

Natural gas storage facilities are generally not publicly owned. They are operated by private-sector companies. In fact, the storage of natural gas can be understood as a service. The operators of the facilities provide the technical infrastructure via tendering procedures. Through them, customers can have their volumes stored or withdrawn and rent the gas storage facilities, so to speak. These are usually energy utilities (gas and oil companies, energy traders, municipal companies such as public utilities). They determine around the clock, 365 days a year, when storage or withdrawal of the volumes they trade should take place.

Good to know: Yes, natural gas is an energy source that has a tough long-term future. As a fossil fuel, it is not compatible with a climate-friendly, greenhouse gas-free world. The situation is quite different with biogas, which is climate-neutral. In the coming decades, therefore, the use of fossil gas as a fuel will gradually be abandoned. Will that make gas storage facilities superfluous? On the contrary, there are already concepts and successful practical projects to repurpose them for storing hydrogen - a very clever new storage solution indeed for renewable energies.

This is how gas storage operators work: Storengy Germany

Not only in France, but also in Germany, ENGIE operates several modern gas storage facilities. Our specialists at Storengy Deutschland's subsidiaries manage a total of six storage sites - including three pore and three cavern storage facilities Storengy has the expertise to operate gas storage facilities safely and efficiently as well as to successfully develop new storage sites. In addition to its core gas storage business, Storengy is already involved in climate-neutral energy solutions such as hydrogen storage and renewable gas generation.

Example project: our gas storage facility in Harsefeld

The Harsefeld natural gas storage facility is one of Storengy Germany's most efficient storage facilities. The facility is located south of Hamburg and went into operation in 1992. Around 107 million cubic meters of working gas can be stored there in two caverns in the Harsefeld salt dome. The caverns are each just under 300 meters high and have a diameter of 50 meters. What is special about the plant is that it achieves a high injection and withdrawal rate and has fast-reacting compressors. This makes it the ideal solution for balancing peak loads quickly and reliably. At full capacity, the storage facility could supply over 50,000 households with gas for more than a year.

Tip: You can find out more about Storengy and the company's wide range of services in the information brochure "The energy of tomorrow starts with you!" (in English).

Our Expert