Sustainable purity for demanding production processes: Coherent LaserSystems relies on ENGIE Deutschland

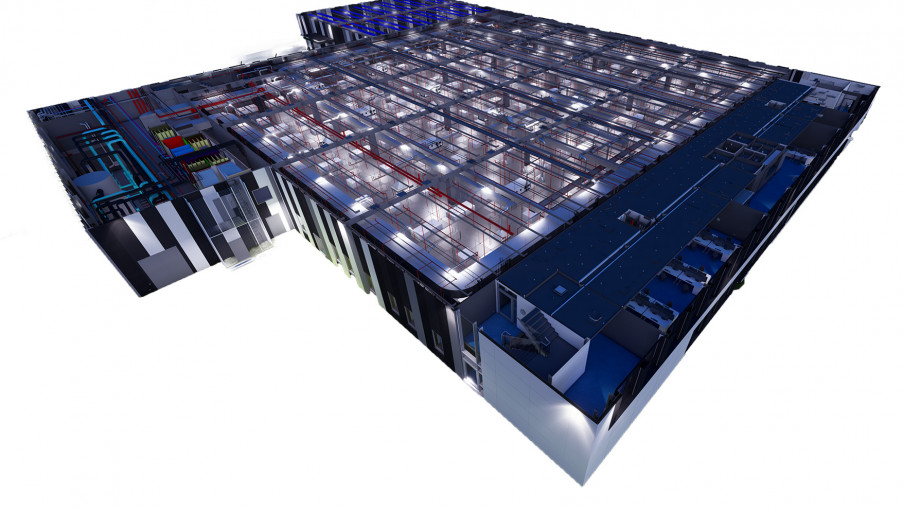

- ENGIE Deutschland is implementing a highly complex cleanroom solution for laser manufacturer Coherent LaserSystems at its Lübeck site, which will send a signal to the entire industry

- In the cleanroom with a total area of more than 3,000 square meters, the specialist for technology, energy and service ensures reliable functionality

- ENGIE Deutschland and Coherent LaserSystems meet the highest standards of economy, efficiency and sustainability with this technically sophisticated concept - thanks to the photovoltaic system and waste heat recovery, among other things

Cologne - In the laser industry, working with particle-sensitive components is the order of the day - and even minimal deviations in the size and concentration of particles can have a significant impact on the quality and functionality of products. Coherent LaserSystems GmbH & Co KG, a leading global provider of lasers and photonics solutions, is therefore relying on the expertise of ENGIE Deutschland GmbH for reliable clean room conditions: in collaboration with Siemke & Co Brücken- & Ingenieurbau (SBI) as general contractor, the specialist for technology, energy and service is responsible for the construction of a production facility for laser systems at the Lübeck site, north of Hamburg. The property comprises around 2,600 square meters of cleanrooms and a further 1,900 square meters for potential cleanroom expansion, 1,100 square meters of laboratory space and more than 3,750 square meters of office, storage and technical space.

Maximilian Busch, Head of Sales & Engineering in the Building Technologies business unit at ENGIE Deutschland, says:

"Cleanrooms have special requirements in terms of personal, product and environmental protection. We at ENGIE Deutschland are proud to have implemented a perfectly coordinated concept for Coherent LaserSystems for the cleanliness requirements of production, which sets standards in terms of cost-effectiveness and sustainability in the cleanroom."

ENGIE realizes lighthouse project for cleanrooms

The new cleanroom for Coherent LaserSystems will meet the requirements of the very demanding ISO 6 classification after its planned completion in December 2025. The ENGIE team of experts will achieve this by using its own ceiling elements and filter units, for example. At the same time, the energy concept focuses on sustainability: ENGIE Deutschland is installing a photovoltaic system with an output of 230 kilowatt peak on the roof of the building, which will contribute to a completely electricity-based, renewable supply. Among other things, it feeds two water-cooled QUANTUM chillers with Green Heat Recovery from sister company ENGIE Refrigeration with a total cooling capacity of two megawatts for the cooling supply. These refrigeration systems with heat recovery make it possible to cover the entire heat requirement for heating the building using the heat generated in the refrigeration process - an approach that has rarely been used in cleanrooms to date. Maximilian Busch emphasizes: "In the new clean room for Coherent LaserSystems, ENGIE Deutschland shows how we can combine the highest standards of functionality and sustainability with the right concept, even in sensitive environments. This makes this project a beacon project with a model character for follow-up projects throughout the industry and fulfills our claim at ENGIE to accompany our customers on their way to climate neutrality in the best possible way." ENGIE Deutschland has more than 30 years of experience in cleanroom technology and implements projects throughout Germany for demanding industries ranging from optics and laser technology, pharmaceuticals, biotechnology and chemicals to plastics and automotive.

High efficiency in a sensitive environment: ENGIE Deutschland is building a sophisticated and sustainable cleanroom solution for Coherent LaserSystems at the Lübeck site.

Your contact

ENGIE Deutschland GmbH